The Benefits of Digital and Die Cutting in Modern Manufacturing

The Benefits of Digital and Die Cutting in Modern Manufacturing

Written By: Brandy Rabalais

In the ever-evolving landscape of modern manufacturing, the pursuit of precision, flexibility and efficiency has become a relentless quest. Traditional cutting methods often fall short in meeting the demands of today's production processes, particularly when dealing with intricate designs, complex materials or rapidly changing requirements. This is where digital and die cutting technologies emerge as game-changers, offering a myriad of advantages to revolutionize manufacturing across various industries.

1. Precision at the Cutting Edge

1. Precision at the Cutting Edge

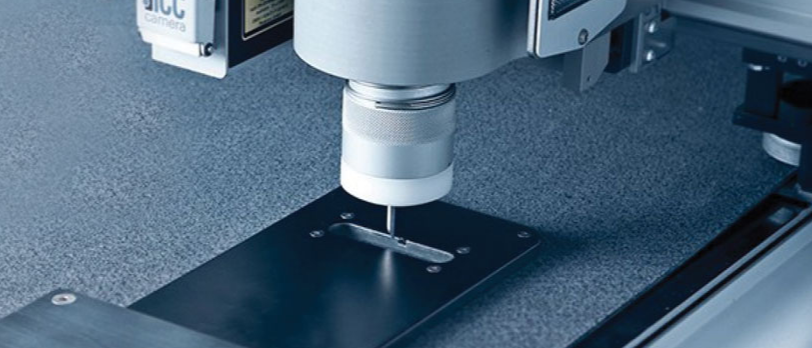

One of the most significant benefits of digital and die cutting is the extraordinary level of precision they offer. With computer-controlled cutting systems like the state-of-the-art Zund S3 digital cutter, manufacturers can achieve incredibly accurate and consistent cuts, even with the most intricate patterns or shapes. This precision translates into reduced material waste, tighter tolerances and higher-quality end products, enhancing overall efficiency and customer satisfaction.

2. Unmatched Versatility

Digital and die cutting technologies are remarkably versatile, capable of handling a wide range of materials. From paper and cardboard to plastics, textiles and even metals, advanced cutting methods empower manufacturers to explore new applications, experiment with different materials and cater to diverse customer preferences without compromising quality or efficiency.

3. Rapid Adaptability for Changing Demands

In the fast-paced world of manufacturing, the ability to adapt quickly to evolving market demands is crucial. Digital and die cutting systems excel in this aspect, allowing for swift changeovers and seamless transitions between different cutting patterns or designs. This agility enables manufacturers to respond swiftly to changing customer requirements, reducing lead times and ensuring timely delivery of products.

4. Cost-Effective Production

While the initial investment in digital and die cutting equipment may be higher compared to traditional methods, the long-term cost savings and operational efficiencies make it a compelling choice. Advanced technologies minimize material waste, reduce labor costs and streamline production processes, ultimately leading to lower overall manufacturing costs and increased profitability.

5. Comprehensive Capabilities

Companies like Ward & Kennedy, with a legacy spanning nearly a century, offer comprehensive digital and die cutting services to cater to a wide range of manufacturing. From prototyping and CAD design to reverse engineering and high-volume production runs, we provide a one-stop solution for businesses of all sizes.

Digital and Die Cutting in Modern Industries

The benefits of digital and die cutting extend across numerous industries, making them invaluable tools in various manufacturing sectors:

Packaging and Printing: From custom-shaped boxes and intricate labels to protective inserts, digital and die cutting enable the creation of eye-catching and functional packaging solutions.

Signage and Displays: Trade show displays, point-of-purchase displays and signage can be precisely cut and shaped for a professional and attention-grabbing appearance.

Automotive: Die cutting plays a crucial role in the production of gaskets, seals and other automotive components, yielding a precise fit and optimal performance.

Textiles and Apparel: The intricate cutting of fabrics, from apparel to upholstery, is facilitated by digital and die cutting, allowing the manufacture of high-quality textile products.

Electronics: The precise cutting of conductive materials, such as copper foil or flexible circuits, is enabled by digital and die cutting, supporting the production of advanced electronic components.

Embrace the Future with Ward & Kennedy

Join the future of manufacturing by partnering with Ward & Kennedy, specialists in cutting-edge digital and die cutting technologies. With state-of-the-art equipment, Ward & Kennedy delivers precision, material versatility and rapid adaptability to evolving demands. Our comprehensive services utilize prototyping, CAD design, reverse engineering and high-volume production runs. Contact us today to learn more!