3M™ Panel Bonding Adhesive, 58115, 450 mL DMS Cartridge, 4 per case

-1

3M™ Panel Bonding Adhesive, 58115, 450 mL DMS Cartridge, 4 per case

Technical Specifications

- Recommended by many OEMs

- Provides corrosion protection with lifetime warranty

- Room temperature curing (accelerated curing with heat)

- Can be weld bonded or rivet bonded within working time

- Adheres to a wide variety of properly prepared steel and aluminum substrates

- May be used on many plastic and composite substrates

- Glass bead technology protects against overclamping and maintains a minimum bond line thickness

- Has excellent shelf life opened or unopened, reducing unused product replacement costs

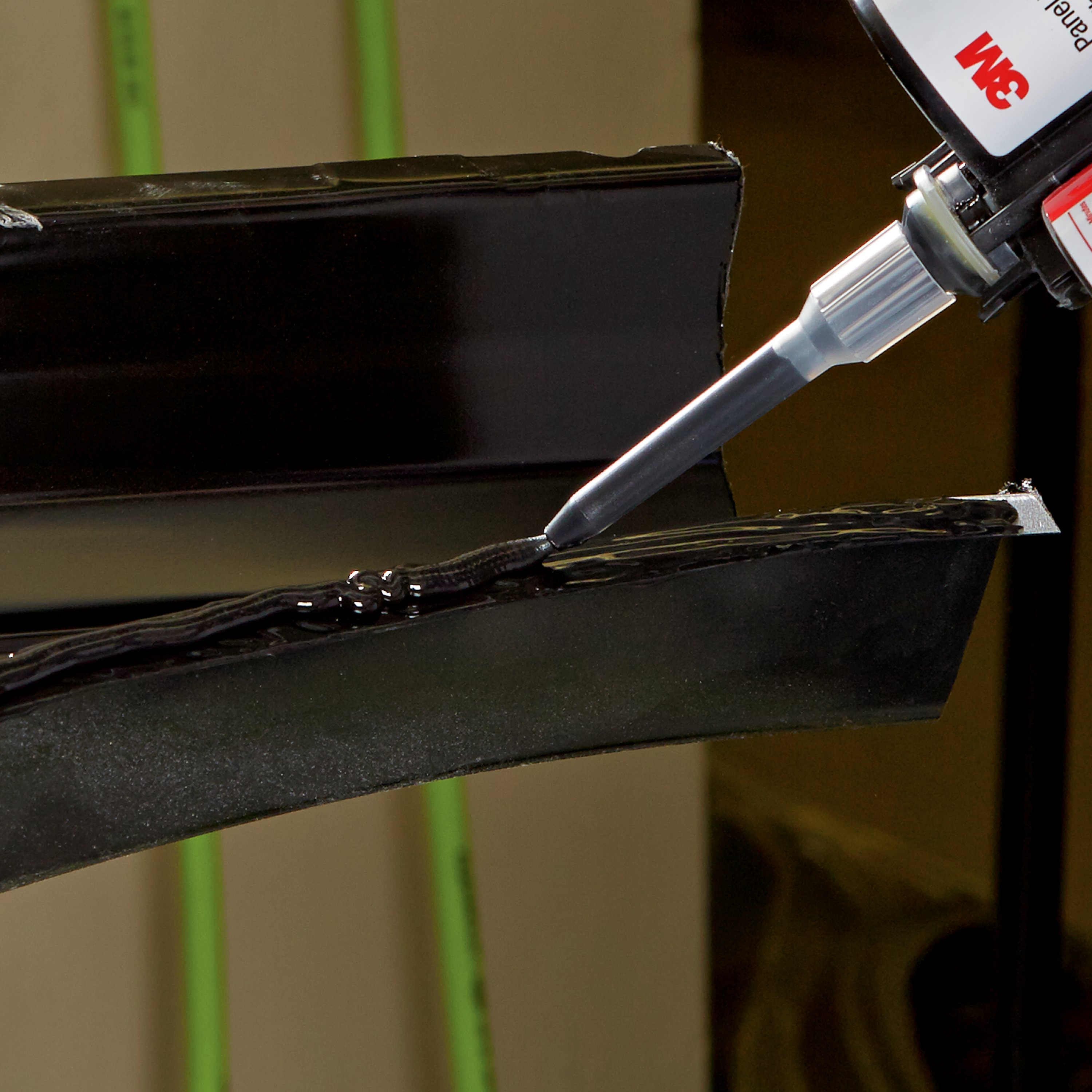

3M Panel Bonding Adhesive provides a continuous bond and seals weld and rivet bonded areas against corrosions

The result of years of development and testing, 3M™ Panel Bonding Adhesive bonds and seals plastic and metal substrates including cold roll steel, aluminum, SMC, and FRP (traditional fiberglass). It is ideal for bonding quarter panels, roofs skins, box sides, van sides, utility vehicle sides and door skins — anywhere that requires a lasting bond for outer body panels - as specified by OEM. Many interior or other adjacent parts that must be removed to avoid damage from welding can remain installed when bonding.

Note: Panel Bonding Adhesive should only be used to bond structural components such as pillars, rockers or frame members when specified by an OEM (Example: Aluminum Ford F-150). Unless specified by an OEM, structural components should be welded.

See Standard Operating Procedures for Aluminum Body Repair (PDF, 3.09 Mb)

Efficient Application

Two-part panel bonding adhesive is available from 3M in cartridges from 50 mL to 400 mL, and works seamlessly with 3M manual applicator guns such as 08117 and the 3M pneumatic applicator gun 09930 for the 200ml cartridges. It applies quickly from the cartridge with no pre-mixing or measuring. The adhesive contains glass beads which reduces excessive squeeze-out and makes it easy to form consistent bondlines. A work time of up to two hours and the added heat-assisted on-demand curing allows for accurate application, squeeze-out sealing and cleanup. The bonding adhesive also has an excellent shelf life even after it's been opened, reducing the cost of replacing unused product.

Better Science for Better Bonding from 3M

3M™ Panel Bonding Adhesive is the result of years of laboratory development and field testing. 3M scientists pioneered "bondline control" in the collision repair market, incorporating glass beads into the adhesive formula that work as built-in spacers for optimal bond line thicknesses. 3M adhesive cartridges, together with manual and pneumatic applicator guns and mixing nozzles, form a system that eliminates pre-mixing or measuring of two-part epoxies. The ability to bond effectively results in a more versatile, cost-effective shop.

Learn More about 3M™ Panel Bonding Adhesive (PDF, 5.85 Mb)