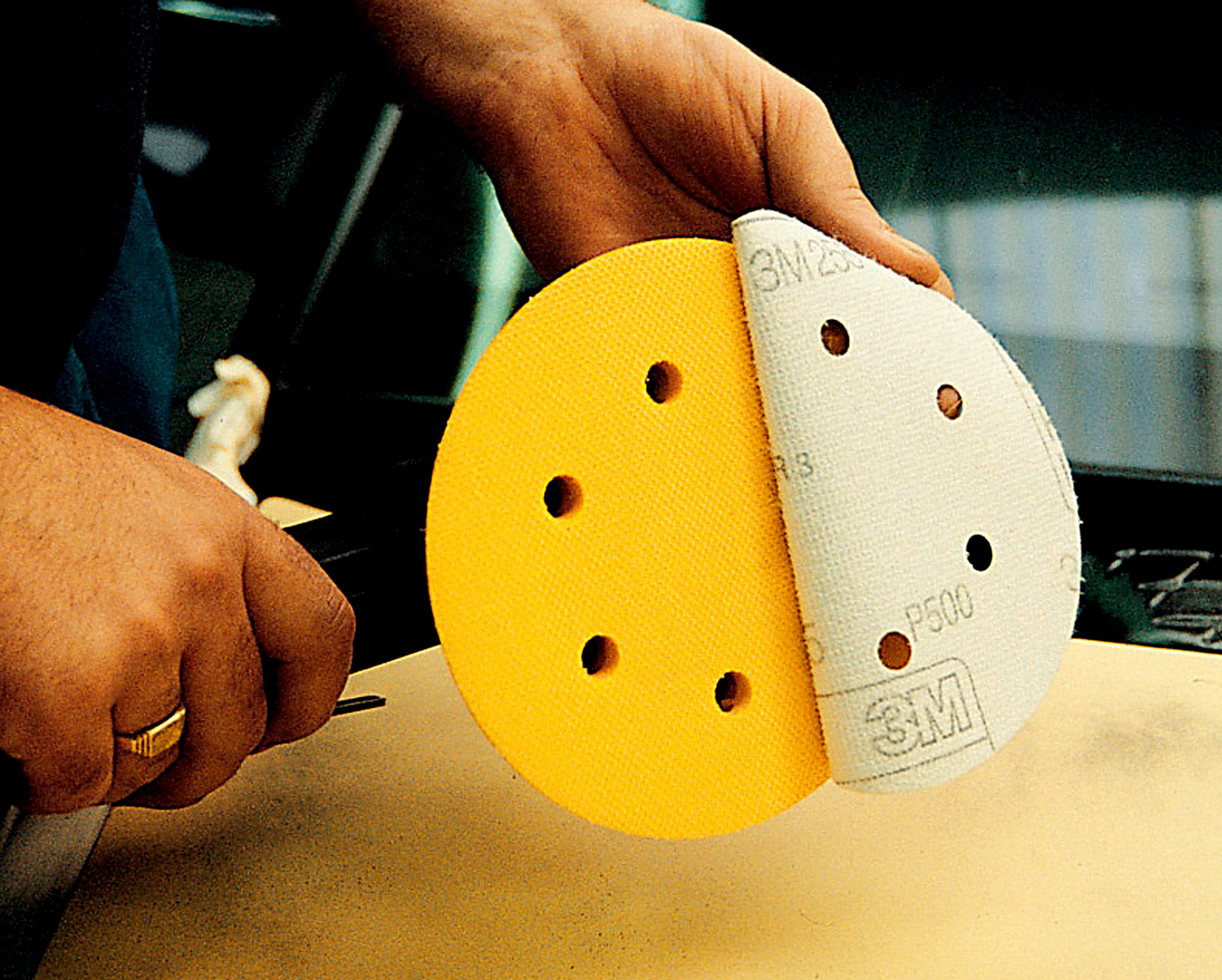

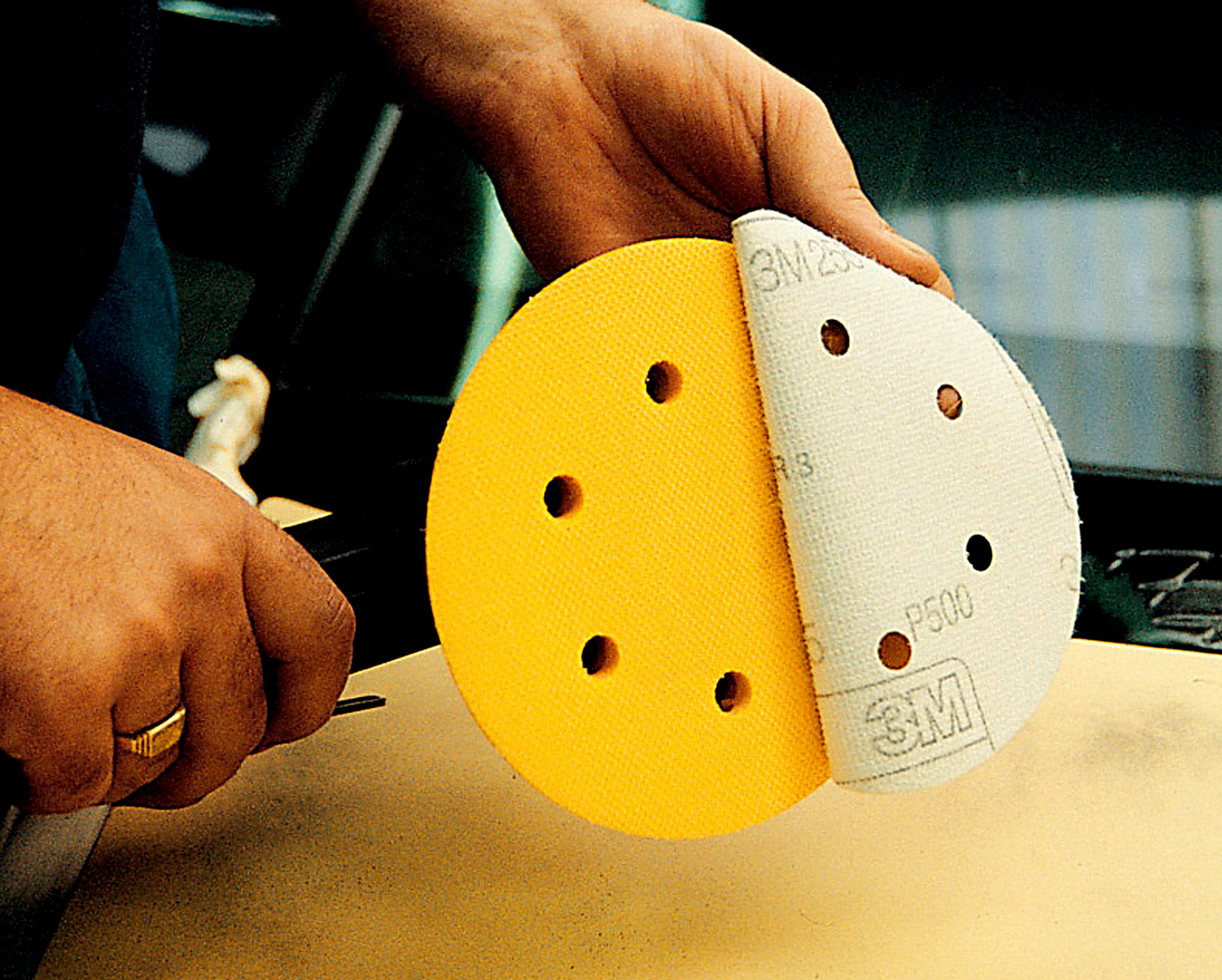

Available in dust-free

Available in dust-free

pads with holes  Also available in

Also available in

pads without holes  Hookit™ attachment system

Hookit™ attachment system

enables easy disc change-outs Hookit™ Abrasive Disc Pads bring new levels of efficiency and performance to a broad range of auto body projects. Specific pads are tapered for sanding projects on flat surfaces or contours, low speed or high. Disc pads feature our Hookit™ attachment system for use with a range of Hookit™ abrasive discs, affording quick change-outs and longer life of disc pads and discs.

Improved Sanding for a Broad Range of Projects You'll find a Hookit™ Abrasive Disc Pad for a broad range of auto body projects including shaping plastic filler, paint stripping, primer sanding and low-speed polishing or grinding. Medium density foam bodies provide support for 3M™ Abrasive Disc Pads (sold separately), yet also provide some flex for good conformability. Discs are available in standard or low profile, and tapered edges range from 15 degrees to 45 degrees, good for flat sanding or for contoured edges, low-speed polishing and featheredging.

Specific Hookit™ Abrasive Disc Pads fit a range of sanding equipment including Chicago Pneumatic® 777 sanders, National Detroit® 900 and Dynabrade® Model 57700 sanders or standard (5/8" shaft) slow-speed polishers. Choose back-up pads designed for use at maximum rpms from 1,500 to 12,000.

About Our Hookit Attachment System The Hookit™ hook-and-loop feature makes disc attachment, removal, and re-attachment clean and easy, and facilitates use and re-use of the disc for the full extent of its abrasive life. Hookit™ disc pads have J-shaped hooks of the type most commonly used in everyday hook-and-loop applications. Hookit™ disc pads grip the brushed nylon loop backings of 3M™ Hookit™ discs and provide a finer finish than do adhesive backed discs. The Hookit™ system is designed for work spaces and applications where adhesive backed discs may become contaminated by dust, dirt, or flying debris.

Better Ways to Sand from 3M Hookit™ Abrasive Disc Pad showcases many of our technologies for better auto body projects, from the material to the taper to the density to the attachment system. Auto body professionals can get the most out of their sanding projects and their operations.