Scotch-Brite™ Deburr & Finish PRO Finishing Flap Brush , 4-1/2 in x 4 in x 5/8-11 in, 6C MED+, 1 per case

-1

SKU: 7010365685

Scotch-Brite™ Deburr & Finish PRO Finishing Flap Brush , 4-1/2 in x 4 in x 5/8-11 in, 6C MED+, 1 per case

SKU: 7010365685

$142.13

/ Each

Add $199.00 worth of items to your cart to qualify for

Sold By: Each

QTY:

SHIPPING DIMENSIONS

Height: 1.25 Inches

Width: 4.50 Inches

Length: 5.00 Inches

Weight: 1 Lb(s) 3 Oz

Technical Specifications

- High-performance alternative to conventional wire brushes and messy compounds

- Open web resists loading, prolonging abrasive service life and contributing to a consistent cut

- 3M Precision Shaped Grain maximizes finishing speeds

- Versatile brush deburrs and finishes in one step

- Excellent for finishing following belt sanding

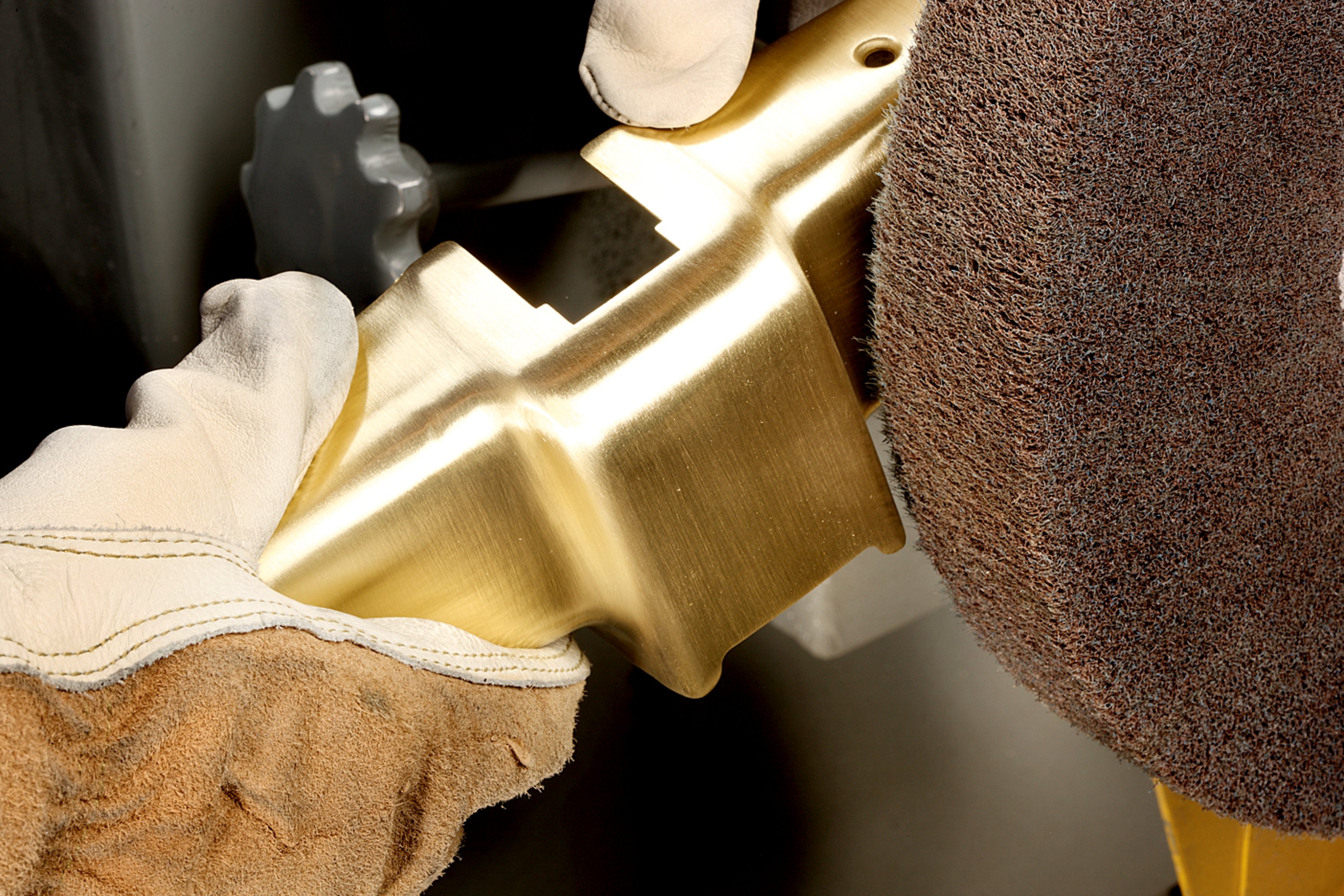

Contoured part finishing

When top product performance is the bottom line, Scotch-Brite™ Deburr and Finish PRO Flap Brush is recommended for cleaning and finishing. This flap brush is designed with all the benefits operators have come to expect from Scotch-Brite™ abrasives, including load resistance and responsive open web that produces an even, consistent finish. What sets this brush apart from other Scotch Brite™ abrasives is 3M Precision Shaped Grain (PSG). This proprietary mineral — coated throughout the abrasive — is engineered for hardness and strength for an exceptionally fast and consistent cut.

The sharp-cutting mineral is counteracted by soft, buoyant nylon fibers that respond to surface irregularities and contours. Gaps between fibers allow debris to escape and help minimize loading. Together, the web and mineral combine to aggressively tackle the substrate without sacrificing predictable results. It produces fine finishes on stainless steel and can clean brass and aluminum to provide a bright finish.

The Outstanding Performance of 3M Precision Shaped Grain

3M Precision Shaped Grain is produced using 3M technology to create triangular shaped ceramic mineral grains. The razor-sharp corners of each triangle act like individual cutting tools that slice through metal, and continuously shelf-sharpen as the points break off, ensuring extended high performance in heavy-duty production applications. The grains wear evenly and provide extra-long life and consistency with less grinding pressure. The result is that PSG products outcut and outlast conventional ceramic industrial abrasive products, maximizing productivity and minimizing operator fatigue.

Blending finishes back into fabricated metal

The Scotch-Brite™ Deburr & Finish PRO Flap Brush is engineered by adhering individual sheets of nonwoven abrasive material to a fiber core at a 90 degree angle. Under normal use (abiding by recommended RPMs), the brush minimizes chatter risk. As it spins, flaps rotate centrifugally and make continuous contact with the workpiece. By lapping the surface, the flaps eliminate the residual traces or marks that tend to be left by singular discs or discs ganged on a shaft.

A flap brush may be used with a variety of tools, including backstands, 3M™ Match and Finish Sander, and Inline Sanders.

The Many Advantages of Scotch-Brite™ Abrasives

Nonwoven technology makes these Scotch-Brite™ industrial abrasives unique. A combination of fiber strands, resin, and abrasive mineral forms a thick, open web. The spring-like nature of the fibers responds to contours and effectively removes unwanted burrs, soils, and contaminants